Innovative Solutions for Plastic Sustainability: A Deep Dive into NIR Laser Marking

Laser marking is a key technology to improve sustainability within the plastics industry. It reduces the need for labels, providing traceability to plastic parts. Laser marks are durable, abrasion resistant and cannot be removed with chemicals. The technology offers speed, flexibility and is cost efficient, because it does not require consumables and involves only minimum maintenance.

The applications for laser marking are numerous, and include animal ear tags, automotive parts, decoration, packaging, personalization and identification of high value items. For these applications, a range of effects can be employed using laser marking. This includes branding and company logos, QR codes and barcodes, and decorative photos or images as shown in Figure 1.

As discussed in the first article of this series, there are three mechanisms for the production of laser marks: carbonisation, foaming and colour change.

Laser marking contrast depends on technology used (NIR, UV, Green or CO2), product/formulation and laser marking parameters. In this article we will focus on NIR laser marking technology which is cost-effective, safe and suitable for most thermoplastics.

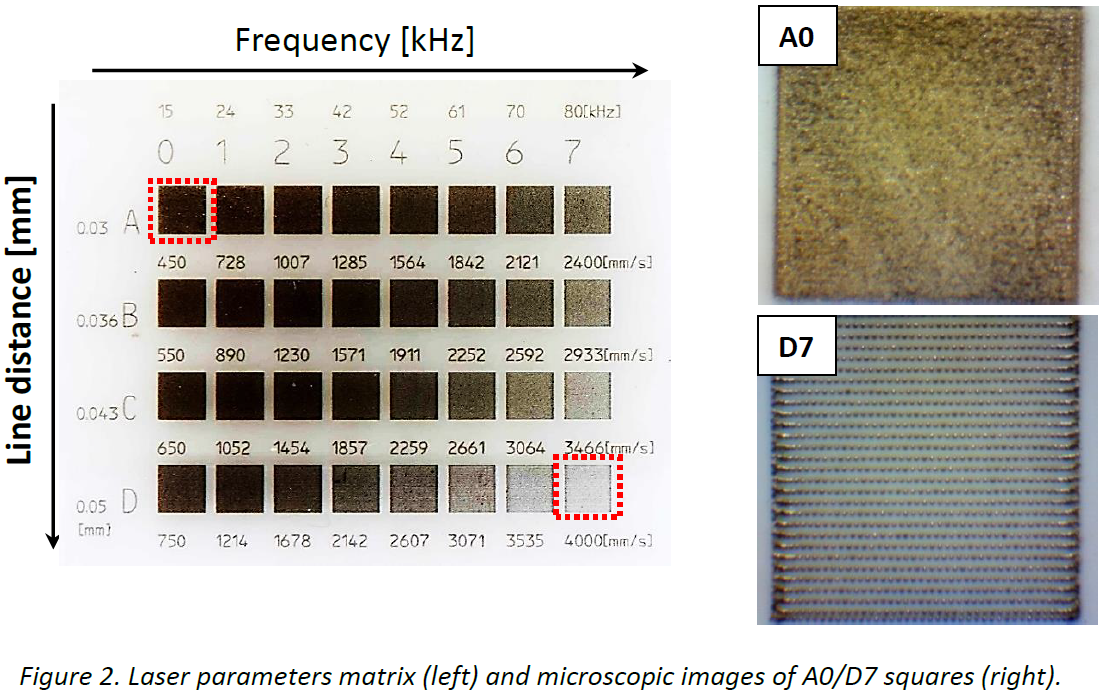

Figure 2 (left) presents a matrix which is typically used to optimize laser marking parameters. For the set laser power, we can vary laser frequency (x axis) and line distance (y axis). Laser marking speed is obtained by multiplying frequency by line distance. The higher the frequency and line distance, the higher the laser marking speed is and typically lower the laser marking contrast. Figure 2 (right) shows the differences between squares A0 and D7, as seen under microscope. A0 square is uniformly covered by carbonisation products, while D7 is dotted with small carbonized, well spaced-out spots.

The matrix shows that for any given type and concentration of laser marking additive, a variety of marks with very different contrast can be obtained. It highlights the importance of choosing the right laser marking settings.

Keeling & Walker Ltd. offers a range of laser marking additives suitable for dark marks on white or coloured polymers as well as light marks on black polymers.

Our additives offer high contrast, disperse easily and do not contain any hazardous ingredients. They are manufactured on our site in Stoke on Trent, to ISO 9001 Quality Assurance Standard. We have well equipped laboratories where we meticulously test all our products with ICP, BET, PSD, TGA, colour analysis and perform application testing with our injection moulding unit and NIR laser marking. We have a dedicated team of scientists who happily assist our customers with testing and help in choosing the right product and marking conditions.

Click Here to Explore Keeling and Walker’s Product Range and Submit A Sample Request.